Sound wave technology can reduce the use of plastic and reagents in laboratories

University of Copenhagen’s climate footprint increased from 2022 to 2023 – and the largest contributor are laboratories. However, technology such as acoustic dispensers can make labs more sustainable by using sound waves to extract more data from less material.

The University of Copenhagen saw an overall increase in CO2 emissions from 2022 to 2023, the university’s new climate account shows. The main reason? An increase in emissions from laboratories.

In 2023, laboratories accounted for the largest share of emissions at the university with 27 %. From 2018 to 2023, emissions went up by 37 %, and last year, laboratory consumer goods such as pipettes, filters and cell culture equipment accounted for 23 % of emissions in laboratories.

Luckily, technology can come to the rescue. For example, automation can help reduce the use of lab consumables in research.

One such automation device is acoustic dispensers, which use sound waves to dispense liquids. These machines can contribute to bringing down plastic and reagent use and thereby emissions, one lab has found.

“Over the years, we have definitely seen a decrease in the amount of plastics and reagents used in our facilities, as we have added acoustic dispensers to our lab and are marketing their use more broadly,” says Sandra Gordon, staff scientist at the High-Content CRISPR Screens lab at Biotech Research & Innovation Centre.

A more precise technology reduces plastic use

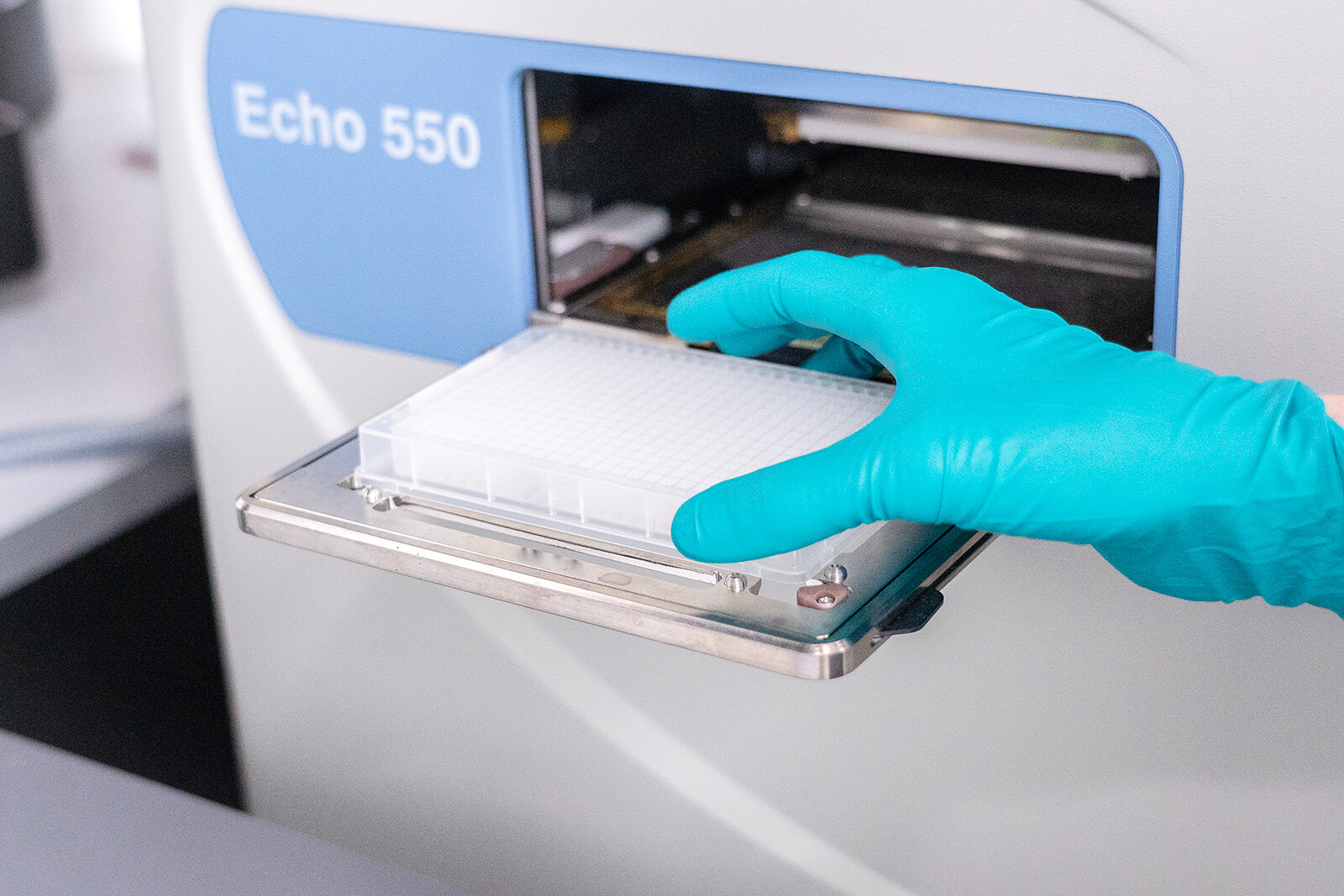

While the acoustic dispensers do not look like much other than big, grey cubes, they essentially act as large, automated pipettes. They handle liquids, such as compounds, antibodies and reagent master mixes, much more precisely and with far less material than manual pipettes.

The machines send sound waves into small cavities or “wells” in a plastic plate containing liquid. This enables the dispensers to shoot droplets of liquid from the wells of one plate into the designated wells of a destination plate. Each well act as tiny test tubes allowing for up to 384 reactions per plate, with one plate using far less plastic than the equivalent amount of individual tubes.

“Acoustic dispensers make it possible for us to extract much more data from the same amount of material and that is a huge benefit when it comes to sustainability,” says Sandra Gordon, adding:

“By using plates, we greatly reduce the amount of plastic used in the lab, as they eliminate the use of test tubes and pipette tips. And because the acoustic dispensers are automated, they can work with far smaller amounts of liquids and are less likely to make untraceable mistakes compared to a manual transfer of liquid. This way we lessen the risk of having to repeat experiments and use additional plastic and reagents.”

Additionally, acoustic dispensers can help optimize the use of materials when working with patient samples and animal samples, where the amount of sample is extremely limited.

Contact

Communications Consultant William Brøns Petersen

william.petersen@sund.ku.dk